Pull-up bar XXL – 4m long as holder for a sling-trainer

Hey guys, of course building a pull-up bar on your own isn’t easy. That’s probably why we get requests every week to modify our standard models or to develop new pull-up bars altogether. Recently we got a request for a XXL pull-up bar that we will describe to you in the following entry.

History

The e-mail we received kind of went like this:

“Hello, in my club I need a holder made of steel for my sling-trainer. It should be built similar to the holder for sling-trainers you already offer. If this is possible, I look forward to hearing from you.”

When I read this, I thought to myself: “hey, we can do anything”. I was happy because I thought we would only have to adjust the already existing holder for sling-trainers. But I was too fast. Since our service is very good, we had all the desired specifications together quickly. And they really differed from those of our other sling-trainer holder.

The Club (to be precise the Fight & Fitness Club in Aalen, Germany) needed a holder larger in size, that should also make pull-ups possible. It should be able to carry 4 people easily. Additionally it should provide space for a maximum of 8 sling-trainers. Due to its size we named the holder XXL pull-up bar.

In general these desired specifications are no problem for us. The main issue with it is that the holder must be attached between two posts that are 4 m apart. Impossible. With a distance this long every normal tube or pipe would bend completely.

In former times we would have said no to constructions like this. But in time we have grown. So we accepted the challenge and found the following solution.

Construction

As mentioned the main challenge is the distance of 4 m, especially considering the weight of the athletes it must carry.

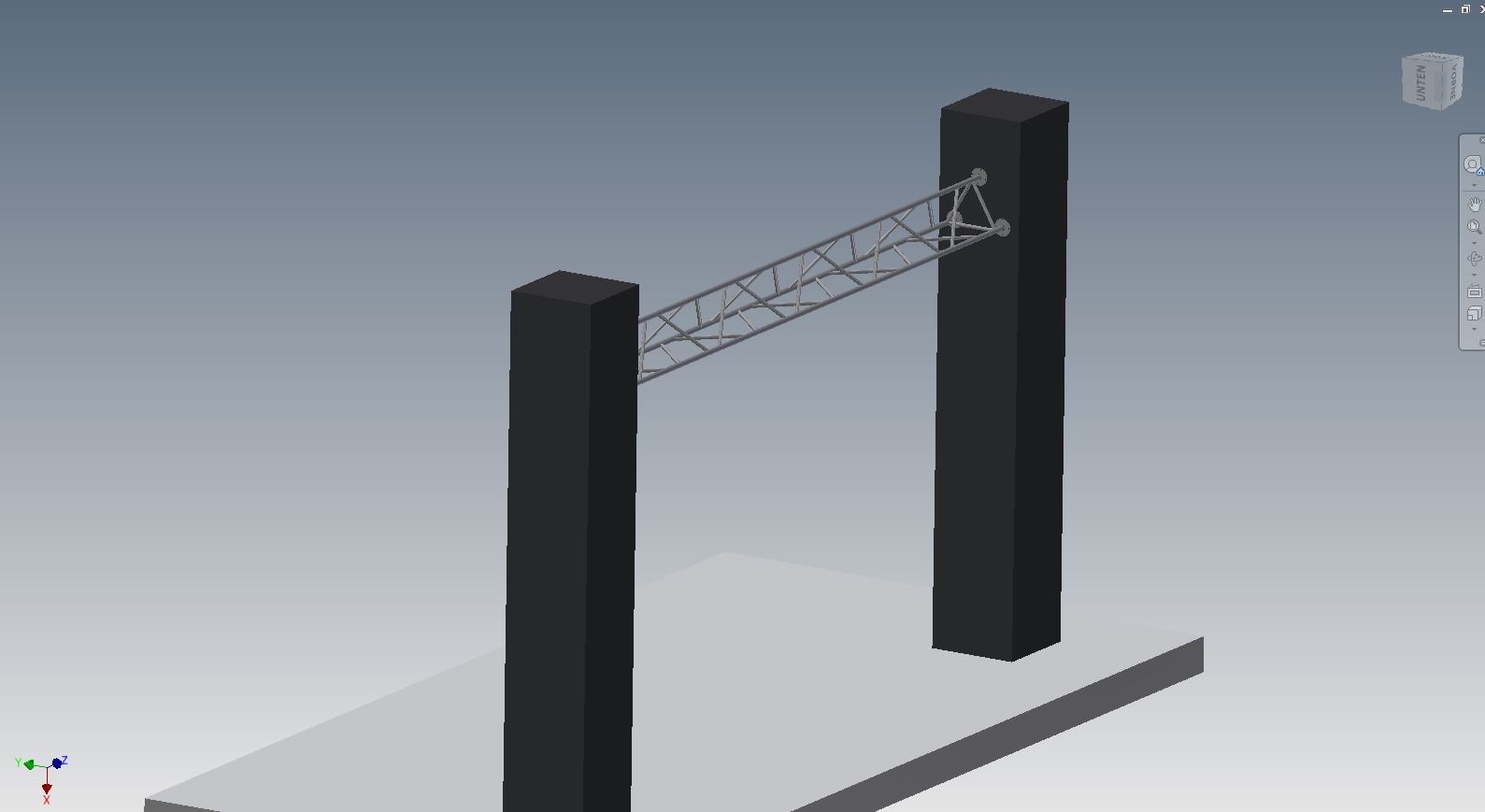

Because of this we decided to use a construction based on the Maxwell diagram (see image below). This method allows a stable construction due to the triplicate in framework structure. It is also used when building crane jibs, since it helps carry very heavy weights.

For the construction we used 30 x 2 mm round shape pipes made of steel for the 3 main columns and 20 x1,5 mm steel round shape pipes for all of the inner struts. The flanges on the columns have a diameter of 100 mm and are 5 mm thick. They are bolted onto the columns with 4 drill holes.

The first 3 images in the gallery show a graphical presentation for the construction.

Trial

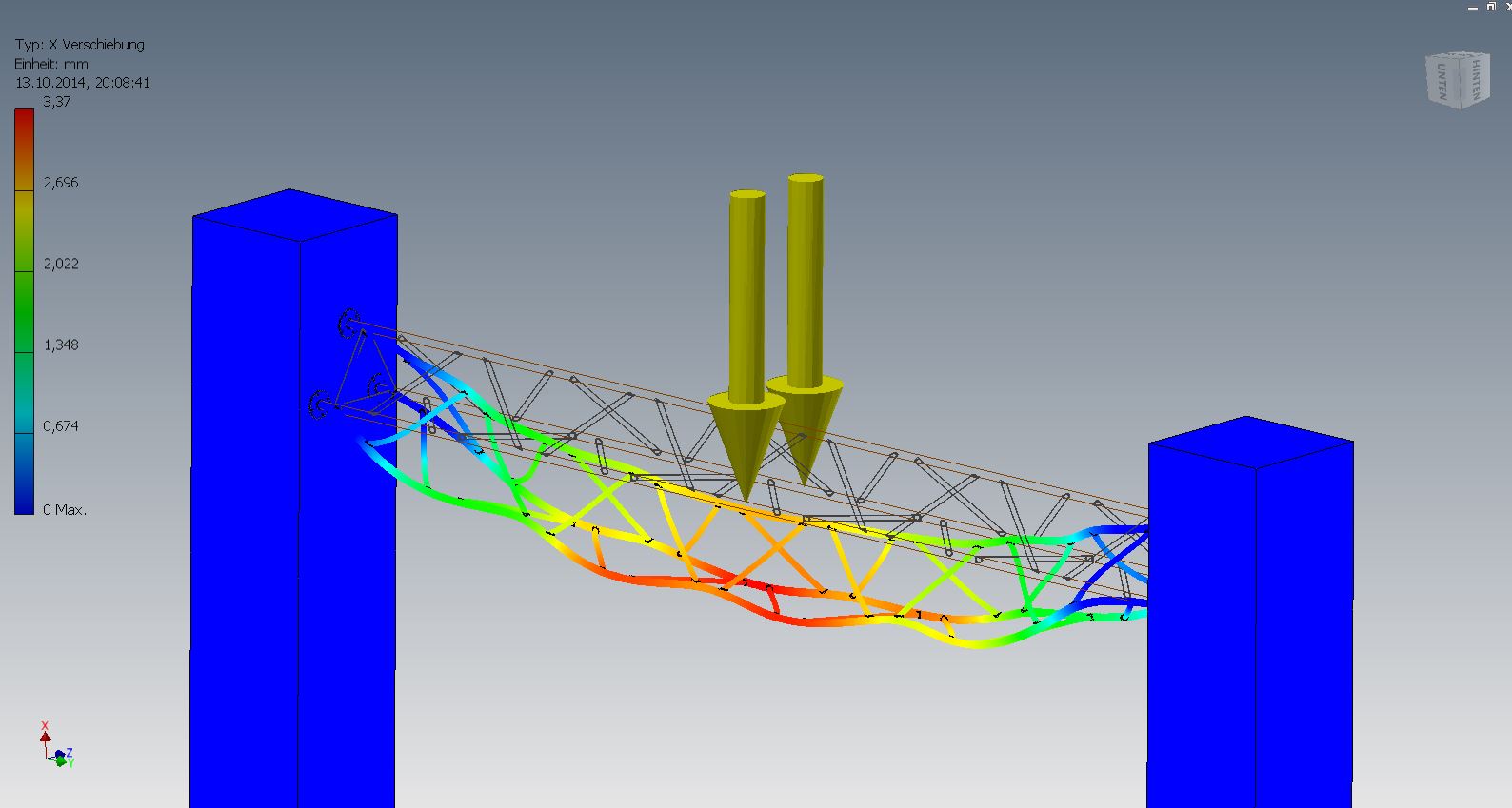

After the construction of the module we went over to the trial phase. We have virtually simulated it according to the FEM simulation. Specifically, we performed two different experiments.

First we cut 6000 N (approx. 611.62kg * m/s^2) in half and the distributed both halves on the two sides of the bar. Each arrow represents a force of 3000 N. We placed the strongest force In the middle of the bar, since this is the area where the highest possible force can occur.

As expected, due to the Maxwell method, the stability of the XXL pull-up bar is tremendous. According to the FEM-simulation the maximum of displacement lies at 3.37 mm at this extent of applied force.

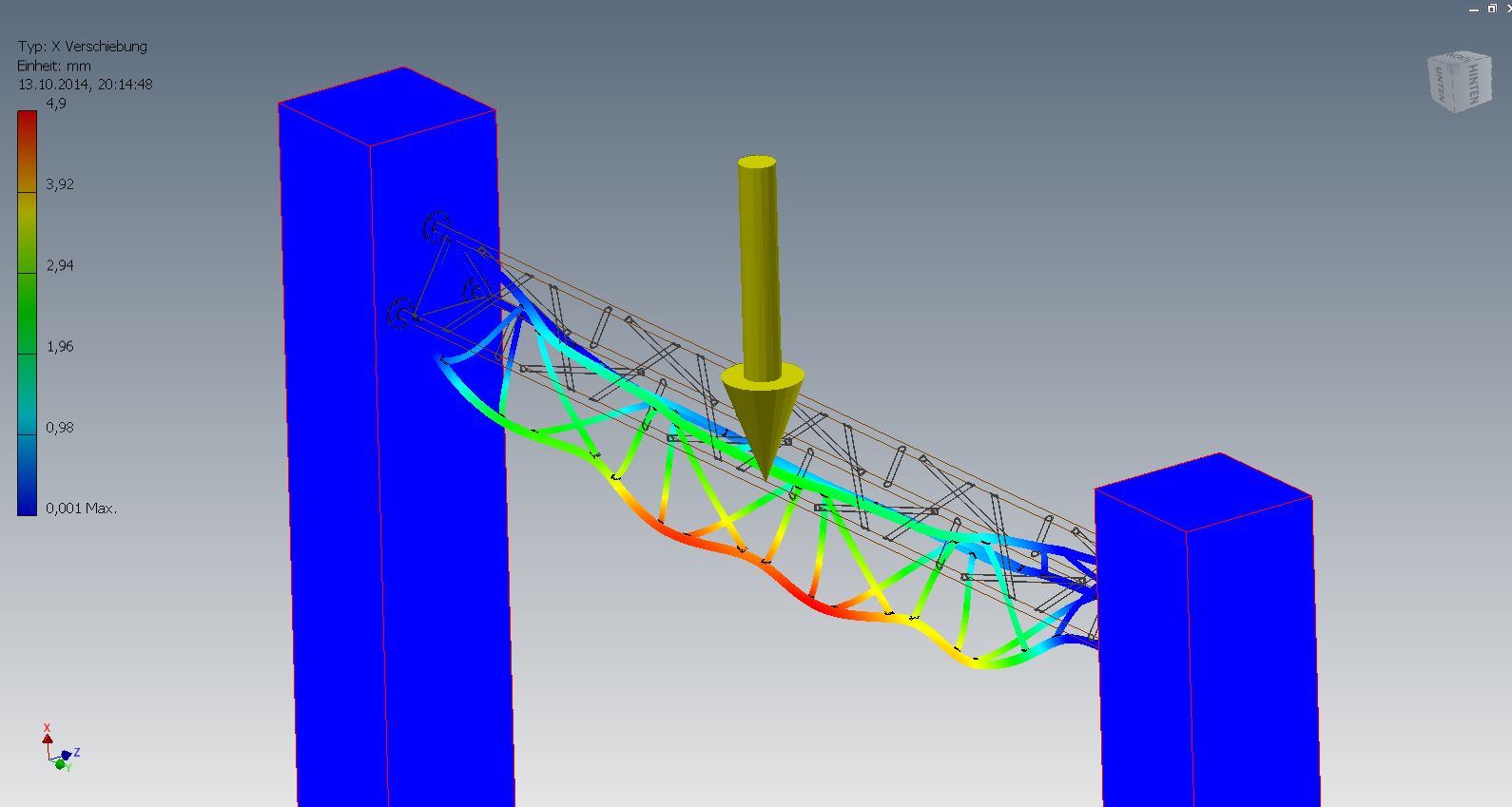

In a second attempt we tried to simulate a worst-case-scenario. This means that we strained the pull-up bar with the entire force of 6000 N on one side.

The simulation shows a maximum of displacement of up to 4,9 mm. This is still within the limits, since this is still far from the boundaries of plastic deformation (see image below with only one arrow).

Due to the one-sided strain, in contrast to the first attempt, we now have additional torsional forces that draw the entire construction around its axis.

For the non-engineers among us: Torsional forces often arise on unevenly strained constructions. This means that we have to assume that the athletes might only train on one side, similar to the situation shown in the simulation. Quite conceivable in reality, so it is possible.

It needs to be taken into consideration that the FEM usually displays situations that are usually very close to reality. The results can also differ from reality though. In the end it depends on the model and if it describes the reality well enough.

The results of a simulation give orientation, but one cannot rely on them entirely. Altogether the FEM offers a simple and optimal foundation, close to reality for the development of difficult projects.

Production

We received the order today. As soon as we have completed the production of the pull-up bar we will add a few photos and a short description of the production process.

Conclusion

All in all this is a very interesting project. Whoever wants to build a pull-up bar himself is welcome to use the information we have given. We are happy to assist you with our expertise and production knowledge.